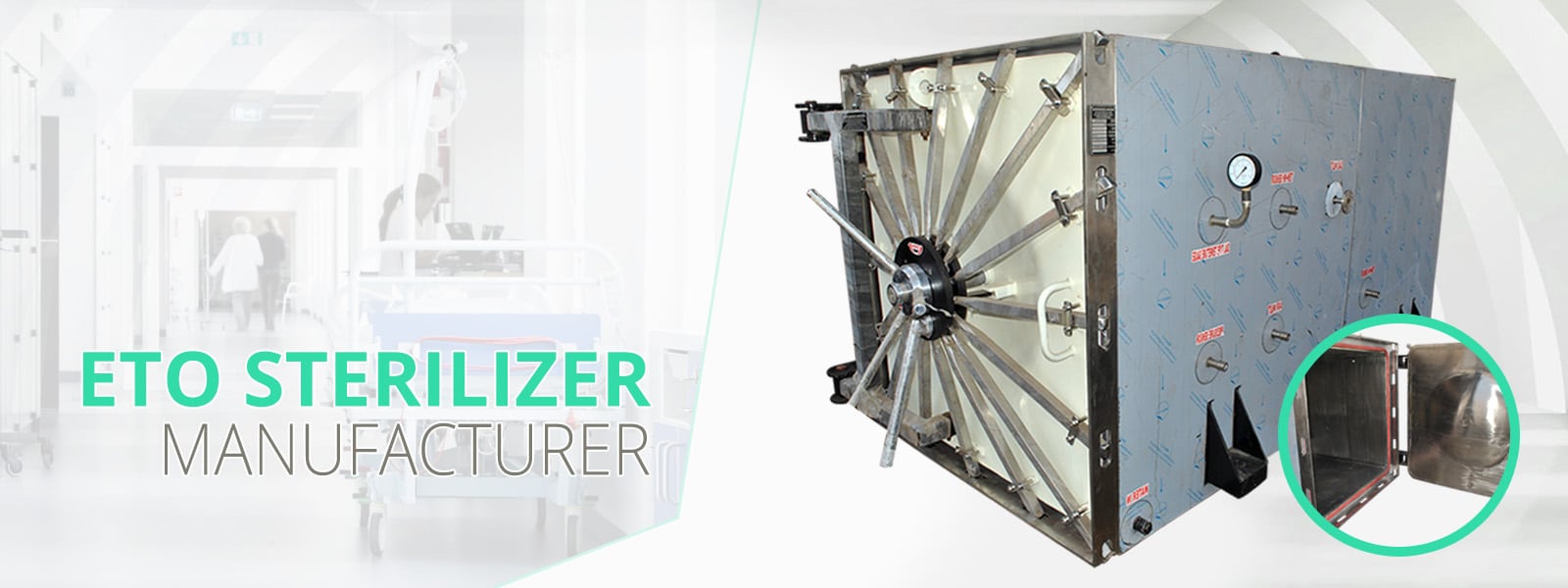

Ethylene Oxide Gas Sterilizer Manufacturer in Ahmedabad Supplier in Gujarat Exporter in India

Incorporated in the year 2000, Krishna engineering is the leading manufacturer, supplier and exporter of top-graded ETO sterilizers in Ahmedabad, India. We are highly engaged in delivering proficiency to the level of ETO sterilizers worldwide. Being on wide expertise we offer ETO sterilizers made from superior quality ethylene oxide gas. We are expert in offering top-grade ETO sterilizers in major parts of India & worldwide. We offer assorted range of products which ranges from bio medical steam sterilizer, continuous steam sterilizers, cylindrical steam sterilizer, food sterilizers, fumigation chambers, herbal steam sterilizers, high pressure steam sterilizer, horizontal steam sterilizer, hospital steam sterilizers, industrial retort, instrument steam sterilizer, medical auto claim, Pharma steam sterilizers, and ribbon blender. Owing to the wide proficiency our highly efficient ETO sterilizers find space in various sectors such as pharmaceuticals, hospitals, medical, chemical, food & beverage, packaging, and various other segments.

- ETO Sterilization Products

ETO

This is what we stand for

Great Services

Highest Standards

Professional Team

Turnkey Solutions

Video Gallery