ETO Sterilizer Manufacturer - Krishna engineering

With Krishna Engineering, you can easily get an ETO Sterilizer at the best price

Ethylene Oxide Gas Sterilizer Manufacturer in Ahmedabad Supplier in Gujarat Exporter in India

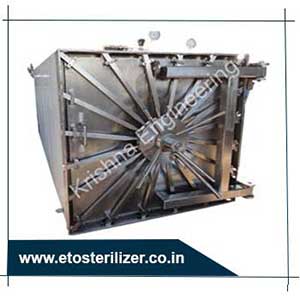

Since the year, 2000 Krishna Engineering Ahmedabad, India is the leading ETO Sterilizer manufacturer and exporter. We distribute ETO Sterilizer in every corner of the world. With comprehensive experience we manufacture ETO sterilizer using high quality ethylene oxide gas. We specialize in supplying ETO Sterilizer in major cities in India and abroad. In our product range, clinical steam sterilizer, continuous steam sterilizer, cylindrical steam sterilizer, food sterilizer, pimples, herbal steam sterilizer, high pressure steam sterilizer, horizontal steam sterilizer, hospital steam sterilizer, Pharma Steam Sterilizer and Ribbon Mix. Our ETO sterilizers are suitable for pharmaceuticals, hospitals, medical industries, chemicals, food and drinks, packaging and many other fields.

ETO Sterilizer Manufacturer & Supplier in India | Krishna Engineering

Krishna Engineering is an Indian ETO sterilizer manufacturer and supplier related to the supply of high-grade sterilization solutions for medical, drug and biotechnology industries. Our designs of the ETO sterilizer are up to international levels so that sensitive tools and materials are efficiently, strongly and safely. Whether it is a sterilization of medical devices, pharma, or laboratory equipment, our design of ETO Sterilizer is safe and effective.

We are a reliable ETO sterilizer supplier in India and offer a comprehensive solution in the form of several sterilization systems. Tailor for each customer, with our products, state -of -the -art technology, provides maximum control over the sterilizing process, ensuring that each piece of tool is properly sterilized. Focusing on user-friendship, safety and energy efficiency, Krishna is your reliable solution for engineering sterilization equipment that completes the work and corrects it every time.

Our ETO sterilizers are ideal for applications where heat-sensitive materials cannot be sterilized using traditional methods. Ethylene oxide gas is used to eliminate bacteria, viruses and fungi, making it perfect to sterilize delicate medical devices, plastic devices, and electronic components. Krishna Engineering ETO sterilizers also fully comply with international rules, ensuring that your sterilization process meets the highest industry standards.

At Krishna Engineering, we pride ourselves on delivering India’s best ETO Sterilizer machines, which are designed with maximum accuracy and care. With an excellent market presence for decades in the sterilizing industry, we have well-catered our products to the market demand with the best quality accompanied by impeccable customer service. We provide the best sterilization solutions for our tiny lab setups as well as for large industrial requirements.

- ETO Sterilization Products

ETO

This is what we stand for

Great Services

Highest Standards

Professional Team

Turnkey Solutions

Video Gallery